月台(码头)最佳实践指南

Usage, safety and maintenance are the power triangle when it comes to maximizing dock area safety and throughput while lowering operating costs.使用,安全和维护是最大化码头区域安全性和吞吐量同时降低运营成本的关键因素。

It's mid-week and your docks are getting busier by the hour. It’s happened before, but this week it just feels more intense than usual.在这个星期中,你的码头越来越忙碌。但对比之前,本周感觉他比平时更加激烈。

And then everything seems to shift to slow motion. What just happened?然后一切似乎都切换成慢动作了。这是什么原因导致的?

Orders continue to be received and picked at a steady pace. Replenishment stock is stored and moved unimpeded. The packaging area is steadily processing orders for shipment.订单继续以稳定的速度接收和拣选。补货库存不受阻碍地存储和移动。包装区域正在稳步处理装运订单。

But wait just a minute. The problem is at the docks. Exactly where you’re standing. But the exact

cause isn’t immediately obvious. It’s time to take a closer look at what keeps your docks receiving and

shipping at peak efficiency.但等一下,问题出在码头上。正是你站在哪里。但确切的原因并不是很明显。现在是时候仔细看看是什么让您的码头接收和发运达到最高效率。

The place to start is dock best practices. They break down into three buckets: usage, safety and

maintenance. Problems in any of the three can bring a DC to its knees. And with good reason.我们从码头的最佳实践开始。他们分为三个部分:使用,安全和 维护。三者中的任何一个问题都可能导致DC瘫痪。并有充分的理由。

Dock area usage, safety and maintenance are all related to each other, says Rich Schlesinger, manager

of U.S. distribution sales at Entrematic. Entrematic的美国分销经理Rich Schlesinger表示,码头区域的使用,安全和维护都是相互关联的。

That said, best practices at the dock start with safety. “Long-term employee health and safety is your leading concern,” says Walt Swietlik, director of customer relations and sales support at Rite-Hite.也就是说,码头的最佳实践始于安全。“长期的员工健康和安全是您的主要关注点,”Rite-Hite客户关系和销售支持总监Walt Swietlik说。

As Schlesinger and Swietlik agree, good safety practices lead to good usage practices. And good

maintenance practices ensure that the dock equipment operates properly without endangering people

or causing bottlenecks.正如Schlesinger和Swietlik所说,良好的安全实践会带来良好的使用习惯。良好的

维护实践可确保设备正常运行,而不会危及人员或造成瓶颈。

In other words, best practices in dock areas is a package deal. Here’s a blueprint for making them

standard practice at your facility.换句话说,码头区域的最佳实践是一整套解决方案。这是在您的工厂进行标准练习的蓝图。

Start with building design从建筑设计开始

Yes, not everyone gets to start with a new building.Often the dock area is what it has been for years.

But consider the principles for good dock design in new buildings as a starting point for upgrades of

existing ones.是的,不是每个人都可以从一个新的建筑开始。通常,码头区域已经存在多年了。但是,考虑将新建筑物中的码头良好设计原则作为现有设施升级的起点。

In both cases, the principle behind dock operations is simple. As Schlesinger puts it, “we all

want docks to load, load, load, and unload, unload,unload all day long. We want it to happen faster and

with greater efficiency. But that doesn’t mean your docks have to be less safe.”在这两种情况下,码头操作背后的原理都很简单。正如施莱辛格所说,“我们都希望码头能够整天装载,装载,装载和卸载,卸载,卸载。我们希望它更快,更高效地发生。但这并不意味着您的码头必须不那么安全。“

The trick is to start with good dock design, says Swietlik. Unfortunately, he says, there is often a

huge lack of knowledge here. Worse yet, it’s dated knowledge. Most people who were once involved

in dock design at their facility haven’t done it in 10 or more years. In that time, for instance, trailers

have gotten longer, wider and lower—impacting dock design.诀窍是从良好的码头设计开始,Swietlik说。不幸的是,他说,这里经常缺乏知识。更糟糕的是,已有的还是过时的知识。大多数曾经参与其设施码头设计的人都没有在10年或更长时间内完成。例如,在那个时候,拖车已经变得更长,更宽,影响更小的码头设计。

There’s a tendency, says Swietlik, to focus on the number of docks that can be jammed into a given

area. “That’s not the best path to safe and efficient dock design,” he says.Instead, Swietlik offers four guidelines for best dock design.Swietlik说,有一种倾向,那就是关注可以堵塞到特定区域的码头数量。“这不是通往安全高效码头设计的最佳途径,”他说。相反,Swietlik提供了四种最佳码头设计指南。

• It starts with a recommended drive approach of 150 feet.首先推荐码头前车场应有150英尺(45米)纵深。

• Door centerlines should be 12 to 14 feet.门宽应为12至14英尺。

• Dock heights should range from 46 to 48 inches.码头高度应为46至48英寸。

• Minimum overhead door space should measure 9 feet wide by 10 feet high.最小顶部门空间应为9英尺宽,10英尺高。

Additionally, expected usage of the docks is a key factor in design. Will 80 trucks use them in 24 hours

or is the number closer to 10? What is the expected load size and weight? Will full truckloads with 30

pallets per trailer dominate? Or will it be less-thantruckload with a pallet or two per trailer? Or, some

combination of the two?此外,码头的预期使用是设计的关键因素。80辆卡车会在24小时内使用它们

还是接近10架?预期的负载大小和重量是多少?每辆拖车有30个托盘的满载卡车是否占主导地位?或者每个拖车有一个托盘还是两个托盘?或者,两者的某种组合?

Equipment selection is critical设备选择至关重要

Clearly, the first step to dock best practices is good dock design. The next step is equipment selection, says Schlesinger, with safety as the underlying premise.显然,码头最佳实践的第一步是良好的码头设计。施莱辛格说,下一步是设备选择,安全是潜在的前提。

“We’ve seen companies in the past couple of years put enormous importance on safety equipment at the dock,” he says. As part of that shift, people are starting to look beyond the initial cost of dock equipment. Now the focus is more on cost over the life span of the equipment and building, exposing greater cost benefits than previously realized.“我们看到过去几年公司对码头的安全设备非常重视,”他说。作为这种转变的一部分,人们开始超越码头设备的初始成本。现在,重点更多地放在设备和建筑的整个寿命期间的成本上,从而比以前实现更大的成本效益。

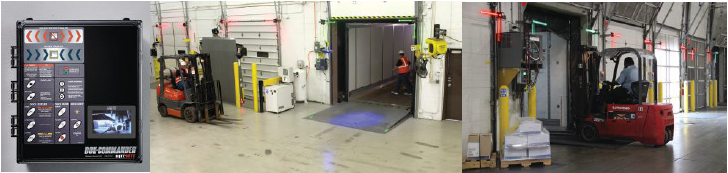

A range of options can improve dock safety (left to right). A master control panel interlocks restraints, doors and levelers.Floor lights indicated the readiness of a dock for use. Lights bracketing each dock door visually communicate that a trailer is secured and it is safe to open the door.一系列选项可以提高码头安全性(从左到右)。主控制面板将限制器,门和校平器互锁。地板灯指示了码头的准备就绪。包围每个码头门的灯可视地传达拖车是固定的,并且可以安全地打开门。

Schlesinger identifies three key areas here: restraints,master control panels and barrier gates.施莱辛格在此确定了三个关键领域:限制,主控制面板和屏障门。

In addition to keeping contaminants outside the building,tight seals also increase energy efficiency.

除了将污染物保持在建筑物外,紧密密封还可以提高能源效率。

“Restraints are an easy and economical way to improve safety,” says Schlesinger. When the trailer is backed into place at the dock, the restraint locks onto the trailer's rear impact guard and securely holds it in place. The alternative is chocks. Unfortunately, chocks are put in place manually and do not secure the trailer as strongly as restraints.限制是提高安全性的一种简单而经济的方法,”施莱辛格说。当拖车在码头上支撑到位时,约束装置锁定在拖车的后部防撞装置上并牢固地将其固定到位。替代方案是楔子。不幸的是,楔块是手动放置到位的,并不能像拖车那样牢固地固定拖车。

“There is now more demand than ever for restraints,”says Swietlik. “It’s an evolution that people have come to realize restraints create a safer environment than chocks.”“现在对限制的需求比以往任何时候都多,”Swietlik说。“这是一种进化,人们已经意识到限制创造了一个比阻塞更安全的环境。”

Furthermore, restraints can be even more effective when linked to a master control panel. That way, nothing happens at the dock, including opening the door, until the trailer is locked in place. In other words, the system locks out all activity until everything is safely in place.此外,当与主控制面板相连时,限制可能更有效。这样,在码头没有任何事情发生,包括打开门,直到拖车锁定到位。换句话说,系统锁定所有活动,直到一切安全到位。

Or as Schlesinger puts it, “a master control panel interlocking the restraint and leveler makes restraints

easier to include in the loading cycle. This is just another example of how safety and usage are joined in

dock best practices.”或者正如施莱辛格所说的那样,“一个主控制面板将约束装置和矫直机联锁起来,使得

装载周期中的约束更容易。这只是安全和使用如何加入码头最佳实践的另一个例子。“

This can be further enhanced with the use of lights bracketing the dock door inside the building. When lit in the upper corners of the door, the lights visually communicate to workers that the trailer is locked in place and it is safe to open the door. Such lighting is typically part of a communication system that makes it possible for everyone in the dock area to know the readiness of a dock for loading and unloading.这可以通过使用包围建筑物内的码头门的灯来进一步增强。当在门的上角点亮时,灯可以在视觉上告知工人拖车被锁定到位并且可以安全地打开门。这种照明通常是通信系统的一部分,该通信系统使得码头区域中的每个人都能够知道码头的装载和卸载的准备情况。

In addition, dock areas are busy places with lift trucks and people making them congested and potentially unsafe.It doesn’t help that loading zones are increasingly squeezed for space, too.此外,码头区域是繁忙的地方,有升降机和人们使他们拥挤和潜在的不安全。加载区域也越来越挤压空间也没有帮助。

There’s also the matter of elevated work areas and the danger of falls. In early 2017, OSHA reissued instructions for guarding against trips and falls from elevated areas. Busy dock areas and falls are where barrier gates and other protections come in to the picture.还有工作区域升高和跌倒危险的问题。2017年初,OSHA重新发布了防止高架地区出行和跌倒的指示。繁忙的码头区域和瀑布是屏障门和其他保护措施进入图片的地方。

Schlesinger says they’re becoming increasingly popular as people try to get the best space usage from a facility while keeping people safe, both on and off lift trucks. Or,as Swietlik says, “painting a yellow line on a floor does not go far enough to protect pedestrians in the dock area.”施莱辛格说,随着人们试图从设施中获得最佳空间使用,同时保证人们在升降平台上下安全,他们正变得越来越受欢迎。或者,正如Swietlik所说,“在地板上画一条黄线并不足以保护码头区域的行人。”

You can choose several different barrier gate designs. Some are fixed position, while others can be opened and closed as needed.您可以选择几种不同的栅栏门设计。有些是固定位置,有些则可以根据需要打开和关闭。

Several other types of guards to protect people and equipment are available. Some are light-based and tie into the master control panel. One identifies traffic indoors at the dock as well as outdoors in the driveway approach to the dock. Another is a ceiling-hung light indicator that shows traffic from various directions.还有其他几种保护人员和设备的防护装置。有些是基于光的,并且与主控制面板相连。一个识别码头室内的交通以及车道进入码头的室外。另一个是天花板灯指示灯,显示来自不同方向的交通。

One other equipment type worth mentioning is the dock leveler. A shift is underway from mechanical

levelers operated by pull chain to air and hydraulic levelers operated with the push of a button.

Mechanical levelers require workers to bend down in an awkward position to pull up the leveler’s spring. Push-button operation eliminates all of that.值得一提的另一种设备是码头矫直机。从拉链操作到空气的机械调平器和按下按钮操作的液压调平器正在发生转变。机械矫直机要求工人在尴尬的位置弯腰以拉起矫直机的弹簧。按钮操作消除了所有这些。

Maintenance is also tied into safety and usage here. Although more costly initially, air and hydraulic levelers typically require less maintenance than mechanical levelers. That means fewer maintenance requirements for non-mechanical levelers and a lower cost of ownership over the lifetime of the equipment and building.维护也与安全和使用有关。虽然最初成本较高,但空气和液压矫直机通常比机械矫直机需要更少的维护。这意味着对非机械矫直机的维护要求更少,并且在设备和建筑物的整个使用寿命期间具有更低的拥有成本。

The tie in to maintenance

Dock area maintenance is a more complicated story today than it once was. It is no longer just about

properly maintaining dock equipment with a lube and oil twice a year by a certi ed technician. Keeping to a routine schedule and inspecting regularly for issues prior to equipment malfunctions still go a long way to ensuring dock equipment operates safely every time.码头区域维护的关系今天比以前更加复杂。它不再仅仅是由经过认证的技术人员每年两次正确维护带有润滑油和油的码头设备。保持常规时间表并在设备故障之前定期检查问题仍然有助于确保码头设备每次都安全运行。

But now, maintenance includes issues such as building seals for energy ef ciency and sanitation,

especially for facilities handling food and beverage.但现在,维护包括建立能源效率和卫生设施的密封件等问题,尤其是处理食品和饮料的设施。

Since 2011, the Food Safety Modernization Act has had a direct impact on docks. Quite simply,

the act pushes to minimize air and water into the building, not to mention rodents. That requires

a tight seal at docks. In addition to keeping contaminants outside the building, tight seals also

increase energy efficiency. Both are important components of maintenance not just for dock

equipment but the building itself.自2011年以来,“食品安全现代化法案”对码头产生了直接影响。很简单,

该法案推动将空气和水最小化到建筑物中,更不用说啮齿动物了。这需要 在码头紧密密封。除了将污染物保持在建筑物外,紧密密封还可以提高能源效率。两者都是维护的重要组成部分,不仅对于码头设备而且对于建筑本身。

Cold-chain wholesale food distributor Certco,for one, uses vertical levelers, high-speed doors and seals to maximize maintenance of its 130,000-square-foot freezer warehouse. The company says it noticed a huge improvement in terms of food safety, sanitation and energy efficiency as a result.冷链批发食品经销商Certco,使用垂直整平器,高速门和密封件,以最大限度地维护其130,000平方英尺的冷冻仓库。该公司表示,它注意到食品安全,卫生和能源效率方面的巨大改善。

Barrier safety gates protect pedestrians and equipment.屏障安全门保护行人和设备。

Certco is just one of many facilities that benefit directly from dock best practices. Fortunately, people are

“becoming more savvy on how to get safer and more efficient while improving maintenance,” says Schlesinger.Certco只是众多直接受益于码头最佳实践的设施之一。幸运的是,人们“越来越精明如何在改善维护的同时提高安全性和效率,”施莱辛格说。

而且,这都是为了他们的利益。Dock最佳实践意味着更少的事故,更高的效率,整体提高的安全性和更低的终身运营成本。

And, it’s all to their benefit. Dock best practices are about fewer accidents, greater ef ciency, overall improved safety and lower lifetime operating costs.

全部 0条评论