Each storage location in a warehouse is assigned a unique address. This includes both fixed storage locations, such as a portion of a shelf and mobile locations such as the forks of a lift truck. Storage locations are expensive because they represent space, with consequent costs of

rent, heating and/or air-conditioning, security, and so on. In addition, storage locations are typically within specialized equipment, such as shelving or flow rack, which are a capital cost. These costs impel us to use storage space as efficiently as possible.

There are two main strategies used in storing product. The simplest is dedicated storage, in which each location is reserved for an assigned product and only that prod- uct may be stored there. Because the locations of products do not change, more popular items can be stored in more convenient locations and workers can learn the layout, all of which makes order-picking more efficient.

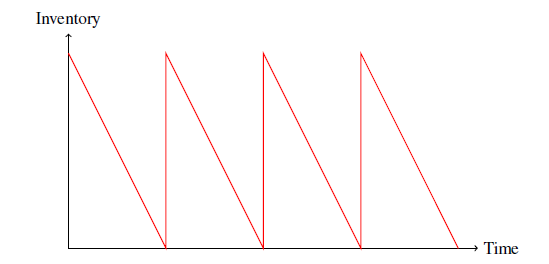

The problem with dedicated storage is that it does not use space efficiently. This can be seen by

tracking the amount of inventory in a given location. If we plot the inventory level, measured for

example by volume, we would see a sawtooth shape such as in Figure 2.5 (which represents an

idealization of the inventory process.) In one cycle the storage location is initially filled but empties as product is withdrawn to send to customers. As a result, on average this storage location is half empty.

Figure 2.5: An idealization of how the inventory level at a location changes over time

A warehouse may have thousands or tens-of-thousands of storage locations. If using dedicated storage, each will have an assigned product. Each product may have a different replenishment cycle and so, upon entering such a warehouse, one expects to see many storage locations that are nearly empty, many that are half-full, and many that are nearly full. On average the storage capacity is only about 50% utilized.

To improve on this, one can use a strategy of shared storage. The idea here is to assign a product

to more than one storage location. When one location becomes empty, it is available for reassignment, perhaps to a different product. This space then can be filled again, rather than waiting until the original product is replenished (presumably when the last of the warehouse supply has been exhausted). The more storage locations over which a product is distributed, the less product in each location, and so the sooner one of those locations is emptied and the sooner that space is recycled. Therefore we expect better utilization of space when shared storage is used.

Unfortunately, shared storage also has some disadvantages. Most immediately, the locations of

products will change over time as locations are emptied and restocked with other products. This

means that workers cannot learn locations and so must be directed to locations by a warehouse

management (software) system. Another disadvantage is that it becomes more time-consuming to put away newly received product because it has to be taken to more locations. There can be other, social complications as well. For example, imagine an order picker who has been directed to the other side of the warehouse to pull a product for a customer. That order picker may be

tempted to pick the product from a more convenient location, thus creating discrepancies between book and physical inventory at two locations. For these reasons, shared storage requires greater software support and also more disciplined warehouse processes.

Shared storage is generally more complicated to manage because it introduces many possible trade-offs. In particular, one can manage the trade-off between space and time (labor) on an activity-by-activity basis. For example, one can retrieve product from the least-filled location (to empty and recycle that location as soon as possible) or from the most convenient location (to

save labor). Similarly, one can replenish product to the most nearly empty location to fill that

empty space or to the most convenient location to save labor time.

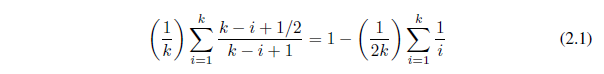

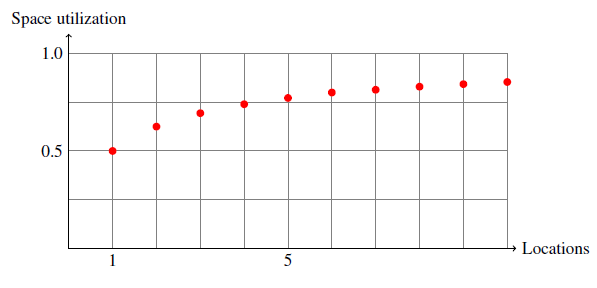

How much improvement in space utilization is possible with shared storage? Consider a product that is requested at a constant rate, as in our idealization of Figure 2.5. Suppose we hold two weeks supply of this product. If we store it in two locations of equal size and direct all order-picking to only one location then after one week, the first location will be emptied and available for reassignment. After the second week the second location will be emptied and available for reassignment. During the first week, the first location was half full on average and the second location was completely full, so that average space utilization was 75%. During the second week the second location was half-full, for an average space utilization of 50%, and the space utilization over the two weeks was 62.5%. More improvement is possible if a product is stored in more locations, though the improvement diminishes and, moreover, the practical problems of management increase.

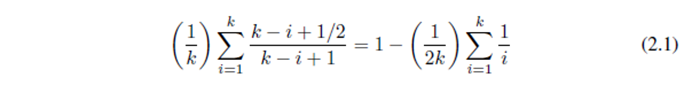

More generally we can argue as follows. Assume for convenience that demand is constant, the SKU has been stored in k locations of identical size, and all picks are from a single active pick

location until that location is exhausted. Then the inventory cycle may be imagined as consisting

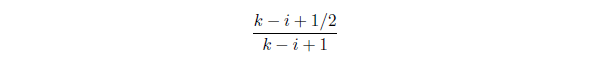

of k periods, each devoted to a particular pick location, as in Figure 2.6. The average space utilization in period i is

and the average utilization over all k periods is

Figure 2.7 shows how the space utilization of storing a SKU in more locations increases but with diminishing returns.

Interestingly, there is a slight sampling bias if one were to examine space utilization directly by

taking a census within the warehouse. This is the subject of Exercise 2.7 and it suggests that you

will tend to measure slightly smaller values than predicted by Expression 2.1.

In practice, a strategy of shared storage is typically used in the bulk storage areas, where most of the volume of product is held on pallets. Dedicated storage may be used in the most active picking areas, which are much smaller than the bulk storage. Thus one gets efficient use of most of the space (bulk storage) with labor benefits where it matters most (active picking areas).

There are also hybrid schemes in which regions are reserved for groups of SKUs, but locations are not reserved. For example, an aisle might be reserved for SKUs of one type or from one vendor, but within that aisle, space would be shared amongst the SKUs.

Figure 2.6: Use of k locations to hold product under a policy of shared storage. The

step function represents the space devoted to holding inventory.

Figure 2.7: Under shared storage, space utilization increases with additional storage locations, but at a diminishing rate.

Figure 2.7: Under shared storage, space utilization increases with additional storage locations, but at a diminishing rate.

Unfortunately, shared storage also has some disadvantages. Most immediately, the locations of products will change over time as locations are emptied and restocked with other products. This means that workers cannot learn locations and so must be directed to locations by a warehouse management (software) system. Another disadvantage is that it becomes more time-consuming to put away newly received product because it has to be taken to more locations. There can be other, social complications as well. For example, imagine an order picker who has been directed to the other side of the warehouse to pull a product for a customer. That order picker may be tempted to pick the product from a more convenient location, thus creating discrepancies between book and physical inventory at two locations. For these reasons, shared storage requires greater software support and also more disciplined warehouse processes.

不幸的是,共享存储也有一些缺点。最直接的是,产品的位置会随着时间的推移而改变,因为这些位置上的原有产品会被售空,并重新储存其他产品。这意味着仓库工作人员不能像固定库位存储模式下那样逐渐熟记产品的存储位置,所以必须通过仓库管理(软件)系统来引导他们到达产品的存储位置。另一个缺点是,上架新产品会花费更多的时间,因为这种存储模式下,同一批产品会占用更多的存储库位。

也可能有其他的社会复杂性。例如,假设拣货人员被订单指引到较远的仓库的另一端为客户拣选产品,拣货人员可能会试图从一个更方便的库位挑选产品,从而造成两个库位的账面库存和实物库存的差异。由于这些原因,共享存储模式下需要更强大的软件支持和更严格的仓库作业流程。

Shared storage is generally more complicated to manage because it introduces many possible trade-offs. In particular, one can manage the trade-off between space and time (labor) on an activity-by-activity basis. For example, one can retrieve product from the least-filled location (to empty and recycle that location as soon as possible) or from the most convenient location (to save labor). Similarly, one can replenish product to the most nearly empty location to fill that empty space or to the most convenient location to save labor time.

共享存储的管理通常更加复杂,因为它引入了许多可能的权衡取舍的因素。特别是,可以在逐个作业项目的基础上做出空间和时间(劳动)之间的权衡选择。

例如,拣货人员既可以从数量最少的库位拣选,以便尽快清空该库位以存储新的商品;也可以从最方便的库位拣选,以(节省人力。同样,上架人员既可以将产品上架到最接近于零库存的库位,以提升该库位的实际存储量;也可以上架到离自己最近的库位,以节约作业时间。

How much improvement in space utilization is possible with shared storage? Consider a product that is requested at a constant rate, as in our idealization of Figure 2.5. Suppose we hold two weeks supply of this product. If we store it in two locations of equal size and direct all order-picking to only one location then after one week, the first location will be emptied and available for reassignment. After the second week the second location will be emptied and available for reassignment. During the first week, the first location was half full on average and the second location was completely full, so that average space utilization was 75%. During the second week the second location was half-full, for an average space utilization of 50%, and the space utilization over the two weeks was 62.5%. More improvement is possible if a product is stored in more locations, though the improvement diminishes and, moreover, the practical problems of management increase.

共享存储能在多大程度上提高空间利用率?考虑一个每天以恒定速率被订购的产品,如图2.5所示。假设这款产品我们保有两周的库存量。如果我们把它均分储存在两个库位,并将所有的订单优先指向第一个库位,一个星期后,第一个库位将被清空释放。第二个星期后,第二个库位也将被清空释放。

在第一周,第一个库位平均处于半满状态,第二个库位为全满状态,因此两个库位的平均空间利用率为75%。在第二周,第二个库位平均处于半满状态(即空间利用率为50%),两周的空间利用率为62.5%。如果一个产品储存在更多的库位,就有可能进行更多的改进,尽管这种改进的程度缩小了并且管理的实际问题也增加了。

More generally we can argue as follows. Assume for convenience that demand is constant, the SKU has been stored in k locations of identical size, and all picks are from a single active pick location until that location is exhausted. Then the inventory cycle may be imagined as consisting of k periods, each devoted to a particular pick location, as in Figure 2.6. The average space utilization in period i is

通常,我们可以这样论证。为了方便起见,假设每天的出库是恒定的数量,SKU被存储在相同大小的k个库位中,并且所有的订单拣选都指向一个库位,直到这个库位库存为0时才指向下一个库位。那么库存周期可以想象为由k个周期组成,每个周期都从一个特定的库位进行订单拣选,如图2.6所示。因此,在第i个周期的平均库存利用率是:

and the average utilization over all k periods is

那么在所有K个周期里的平均库存利用率是:

Figure 2.7 shows how the space utilization of storing a SKU in more locations increases but with diminishing returns.

图2.7展示了在一品多位情况下的空间利用率如何增加,但增速在递减。

Interestingly, there is a slight sampling bias if one were to examine space utilization directly by taking a census within the warehouse. This is the subject of Exercise 2.7 and it suggests that you will tend to measure slightly smaller values than predicted by Expression 2.1.

有趣的是,如果要通过在仓库内进行普查来直接检查空间利用率,则会存在轻微的抽样偏差。这是练习2.7的主题,它表明你会倾向于测量比表达式2.1所预测的数值略小的值。

In practice, a strategy of shared storage is typically used in the bulk storage areas, where most of the volume of product is held on pallets. Dedicated storage may be used in the most active picking areas, which are much smaller than the bulk storage. Thus one gets efficient use of most of the space (bulk storage) with labor benefits where it matters most (active picking areas).

在实践中,共享存储策略通常用于大容量存储区域,其中大部分产品存储在托盘上。在畅销品的拣选区域可以使用专用库位存储模式,这些区域比大容量存储库位小得多。因此,人们可以有效地利用大部分空间,并在最重要的地方(畅销品区域)获得效率优势。

There are also hybrid schemes in which regions are reserved for groups of SKUs, but locations are not reserved. For example, an aisle might be reserved for SKUs of one type or from one vendor, but within that aisle, space would be shared amongst the SKUs.

还有一些混合方案,为sku组保留固定的区域,但不保留固定的库位。例如,可能为同一种类型的sku或来自一个供应商的sku保留一个通道,但是在该通道中,库位将在sku之间共享(或者称为变换)。

Figure 2.6: Use of k locations to hold product under a

This guy is lazy,Introduction has not been set