By ID Label · November 12, 2020

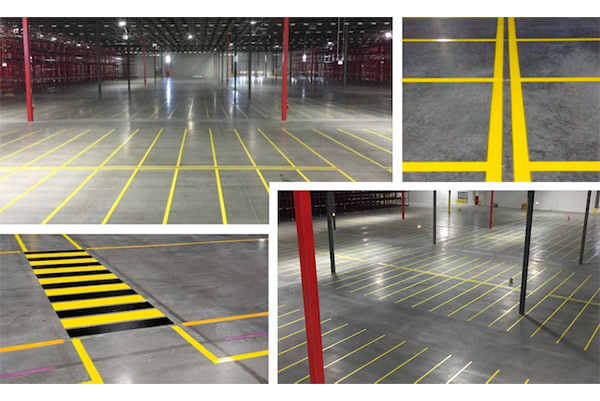

Warehouse floor marking, also known as warehouse floor striping, is the process of using floor marking epoxy paint or tape and floor safety signs to create visual cues for your team. Warehouse floor markings divide spaces, highlight hazards, outline workstations and bulk storage locations, direct traffic, and convey important safety information. Ultimately, these visual cues make it easier for employees to navigate the warehouse while helping to improve warehouse efficiency.

Here are some key reasons why many warehouses use industrial floor markings:

Warehouse Organization 整体运行井井有条– Any increase in warehouse organization will reduce wasted time and energy. For example, bulk storage floor markings—where certain equipment, supplies, pallets or raw goods are stored—should be paired with overhead barcode signs for efficient tracking and management of these items.

Lean and 5S Methodologies精益和5S的有效执行 – Proper floor markings can help warehouses more effectively follow lean or 5S standards. Properly striped floors improve warehouse safety, keep warehouse bulk storage items neatly organized and ensure that space is used efficiently.

Traffic Direction 动线指引– Warehouse floor tape is often used to promote forklift safety by letting operators know where they should be driving, in which directions, and at what speed. Tape can also be used to mark pedestrian pathways and intersections.

Warehouse Personal Protection Equipment (PPE) 员工个人防护– Marking warehouse floors can alert employees when warehouse PPE is required. For example, your facility may use a dotted red line to indicate that a hard hat is required beyond a set point.

Effective floor marking, as required by the Occupational Safety and Health Association (OSHA), creates a visible, standardized system that is easy for employees to understand at a glance.

A floor marking system that also incorporates floor marking color standards can improve both safety and efficiency. For example, a standard yellow floor marking can be used to designate aisle ways, traffic lanes and work cells. Yellow and black striped floor markings can indicate areas that may expose employees to physical or health hazards.

Whether following OSHA guidance on color usage or adopting an alternate set of standards, warehouse floor marking colors need to be consistent and employees need to be trained on their meanings as it relates to your warehouse.

Floor marking is often part of a larger visual communication system that includes overhead warehouse signs. These signs are highly recommended for identifying and managing bulk storage inventory. They typically contain a barcode image and human-readable numbers or letters and work in conjunction with long-range mobile scanning devices.

In addition to overhead warehouse signs, floor safety signs can also help communicate specific messages on warehouse floors with text and images to relay important safety or logistics information.

This guy is lazy,Introduction has not been set