Enterprise Resource Planning and Warehouse Management System are the backbone systems to any distribution center, wholesale, supply chain or FMCG business. Without them, these businesses wouldn’t be able to function.

What is ERP software?

Enterprise Resource Planning (ERP) is a business management software that integrates key areas and automates business processes across all departments of an organization like purchases, sales, marketing, human resources, services, inventory, financial management, etc., and it improves the flow of information across the organization. ERP has some functionality to handle warehouse management processes which has less complexity.

What is WMS software?

A warehouse management system (WMS) is a software application, designed to support warehouse or distribution center management and staff. These applications can manage the various operations, tasks and activities of moderate to complex warehouse or distribution centers (DCs).

Why do we need Warehouse Management Systems over an ERP?

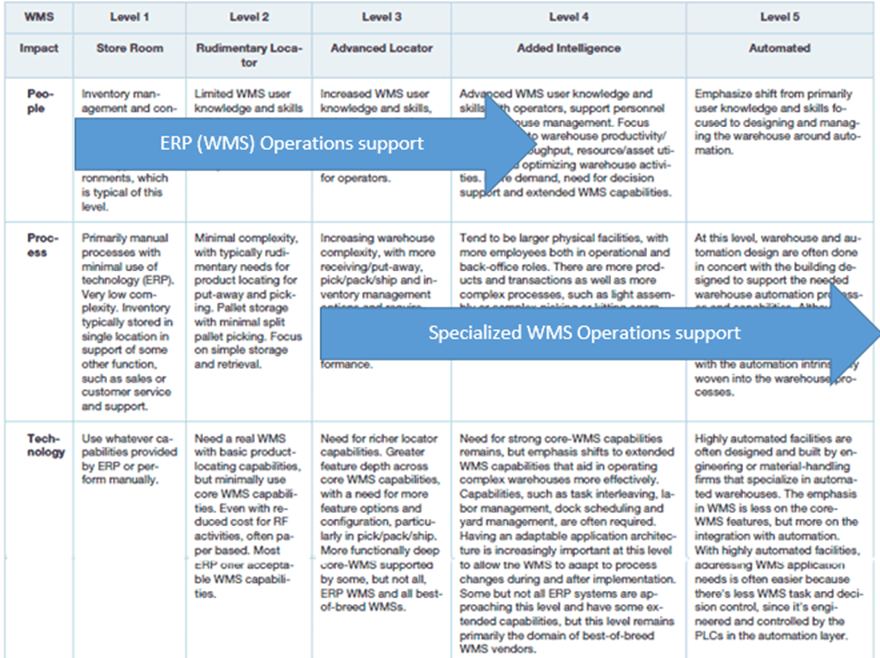

All Warehouses are not same and in the same way all Warehouses Management Systems are not same. An ERP supports to a warehouse to an extent, if the warehouse process are less complex then we need to go with a specialized WMS to a warehouse. We can classify warehouse into five different levels as below:

Level1 –Store Room

Level 2 –Rudimentary Locator

Level 3 –Advanced Locator

Level 4 –Intelligent

Level 5 -Automated

Level 1 – Store Room:

Minimal usage of Technology

Less Complexity

Inventory is typically stored in single location and locations are predefined

Operations are performed manually

Level 2 – Rudimentary Locator

Usage technology for tracking pallets

Multi location inventory

Put away, receiving and minimal put way options

Operations are performed manually

Level 3 – Advanced Locator

Increasing warehouse Complexity

Receiving , put away, packing shipping and inventory managed options

Support of RF devices

Focus on improving warehouse performance

Level 4 – Intelligent

More people driven process both in operations and back office roles

Operations are typically more complex and sophisticated with higher volumes.

Requires robust decision support to optimize operations

Advance level of picking, replenishment.

Level 5 – Automated

Highly automated warehouses operations

Design are driven by engineering firms

Specialized systems are required.

Source Gartner- 2014

Source Gartner- 2014

What can we expect from advanced and specialized WMS?

Mobile Productivity

License Plate Management

Collaboration

Multi Usage Platform

Real Time Information

Advanced Receiving

Event Management

Advanced Put-away Optimization

Advanced Pick and Pack

Advanced Shipping

This guy is lazy,Introduction has not been set